Warning: A non-numeric value encountered in /home/request/domains/requestcracks.com/public_html/helpers/functions.php on line 230

FeatureCAM *Dongle Emulator (Dongle Crack) for Sentinel SuperPro*

FeatureMILL2.5D includes the following features for part creation.

FeatureMILL2.5D includes the following features for part creation.

Holes - Counter-bore, counter-sink, tapped or other types of holes

Pockets - With an unlimited number of islands at a variety of heights

Grooves - Engraving, OD, ID and face grooves

Bosses - Unlimited number of bosses at a variety of heights

Thread Milling - OD or ID threads

You have the option to apply draft angles, chamfers and bottom radii to the walls of any milled features. These can be manufactured using flat end, ball end or tapered tools. Also you can quickly create radial, linear, rectangular and point list patterns of features by entering a few additional dimensions.

Manufacturing Details

Feed Rate Optimization

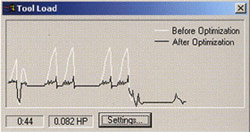

Tool load can vary throughout a toolpath due to increased depth or width of cut. FeatureMILL2.5D&qout;s feed rate optimization minimizes these variations by automatically adjusting feed rates based on tool load. In the following graph, the white curve shows the original tool loads and the black curve shows the loads after feed rate optimization. FeatureMILL2.5D&qout;s feed rate optimization minimizes and evens tool wear, and provides faster running programs.

Manufacturing Details:

Numerous milling and drilling options are included with FeatureMILL2.5D.

� Ability to. rough using cutter comp

� Multiple roughing and finishing diameters can be set for face features

� Bottom leave allowance and bottom finish allowance on semi-finish pass

� Multiple region support for solid stock to eliminate cutting air

� Chamfered, counter bore, counter-sink, tapped, counter-drilled, reamed holes

� Multiple roughing tools (larger to smaller) for fast material removal

� User definable milling tool holders

� Minimize retracts or tool changes

� Tool life management

� Precise tolerances � Extensive drilling and milling macros

� Part line programming

� A variety of toolpath options

� Trochoidal toolpath for simple slots and grooves

� Climb / conventional milling

� Pre-drilling, helical or zig-zag approach

� Peck drilling

� Pilot drilling

� Arc / line approximation for toolpaths

� Multiple stepover types

� Cutter comp or part line paths

� Machining time estimates

� Inch and metric dimensions

Related news:

NCspeed, WorkNC MachineSim *Dongle Emulator (Dongle Crack) for Aladdin HASP SRM*SurfCAM (c) surfcam *Dongle Emulator (Dongle Crack) for Sentinel SuperPro*

StoneCAM, InterCAD, WinGlassCAM (c) Intermac *Dongle Emulator (Dongle Crack) for Aladdin Hardlock*