Warning: A non-numeric value encountered in /home/request/domains/requestcracks.com/public_html/helpers/functions.php on line 230

COMPRESS (c) Codeware *Dongle Emulator (Dongle Crack) for Aladdin HASP SRM*

COMPRESS Features and Benefits

COMPRESS Features and Benefits

Keep up to date with the latest Code Addenda

Not only is COMPRESS kept current with the ASME Code, all Addenda are available from within the same COMPRESS release. There is no need to keep multiple software versions installed to work on vessels constructed to various Addenda. In addition, any number of COMPRESS versions may be installed on the same computer, a handy feature when executing projects which may span several years.

Let COMPRESS be your expert assistant

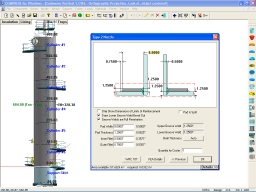

To best suit your project and personal preferences, COMPRESS offers two approaches to modeling vessels: Wizards and free form design.

For quick model creation, COMPRESS includes a Wizard interface. The COMPRESS Vessel Wizard requires only basic information to model typical vessels. Nozzles, for instance, are entered in batches using a simple list. For added convenience, any complete vessel file can be converted into a custom Vessel Wizard template, saving redundant data entry.

Individual components can be designed without specifying the entire vessel. You can also access the COMPRESS Component Wizards directly. For example, the Nozzle Wizard automatically selects nozzle details such as wall thickness, weld sizes and will add a reinforcing pad if required. The Appendix 2 Flange Wizard requires only that the basic design parameters be input and creates optimal custom flanges automatically.

For unparalleled flexibility, COMPRESS offers a component by component free form design approach. This method is useful when designing vessels which do not fit typical parameters and when modifying vessels created by Wizards.

No matter which approach you choose, our standard Windows interface makes learning to use COMPRESS easy. The realistic and accurate vessel depictions offer an intuitive interface and input error traps serve as Code rule reminders.

Entry modes tailored to your needs

Whether you are building new vessels or rating existing equipment, you can build your model using a specially tailored input mode.

In design mode, COMPRESS selects sizes, thicknesses and ratings so as to meet Code requirements while speeding the process of creating a vessel or exchanger design.

In rating mode, COMPRESS calculates the pressure rating (MAWP) andor minimum thickness while allowing you to input the geometry you have. To help you focus on potential problems areas, the COMPRESS Deficiencies Summary highlights components which do not meet Code requirements. In selected circumstances, warnings and other ""good engineering practice"" reminders are presented.

Freedom from geometric restrictions

COMPRESS handles geometries ranging from individual components to complete vessels and exchangers. COMPRESS is able to work in metric (SI and MKS) and U.S. customary units. The metric provisions of Section VIII and the Metric Edition of Section II, Part D are included. This flexibility makes COMPRESS ideal for use in new construction, re-rating existing equipment and performing fitness-for-service calculations.

Let COMPRESS manage the details, an integrated model approach

COMPRESS manages the details so you can focus on the big picture. As you create a model, all previously input components (objects) are re-evaluated in real time as necessary. Key component properties, such as minimum required thickness and maximum allowable working pressure (MAWP), are continuously updated to reflect the inter-dependencies of the components as defined by the applicable Code rules. A simple example of this is the way a liquid level object in COMPRESS interacts with other vessel components to determine the static head of liquid to add to the design pressure. A more complicated example is the way a wind load interacts with the bolting force used to size a flanged tube sheet extension in a vertical heat exchanger.

The primary benefit of this technology is that you do not need to retroactively change component inputs after they have been created. This reduces design errors and enables you to focus on higher level engineering activities.

Go beyond the ASME Code

The task of designing vessels and exchangers is not limited to the rules of the ASME Code. External forces, moments and loads may be specified to act on both the main vessel and nozzles. Local stresses at discontinuities and nozzles are calculated as appropriate. Forces and overturning moments due to weight, wind and seismic loads are automatically determined and applied based on the Building Code selected. COMPRESS also provides an alternative way to input external forces and moments through the user defined wind and seismic options. COMPRESS designs support saddles, lugs, anchor bolts and base plates. COMPRESS provides a lift lug

igging analysis for investigating the various requirements associated with vessel erection.

Time saving user interface

It is important to be able to easily edit your models. By right clicking on the object of interest, you can bring up the appropriate data entry dialog. A tree list is also available if you prefer. When questions arise during data entry, context sensitive help is available.

Related news:

PVElite 2009, TANK 3.1 (c) COADE, Inc. *Dongle Emulator (Dongle Crack) for Aladdin HASP SRM*HYPACK Survey (c) HYPACK, Inc. *Dongle Emulator (Dongle Crack) for Aladdin Hardlock*

ER Mapper 6.2 (c) Earth Resource Mapping, Inc. *Dongle Emulator (Dongle Crack) for Aladdin Hardlock*